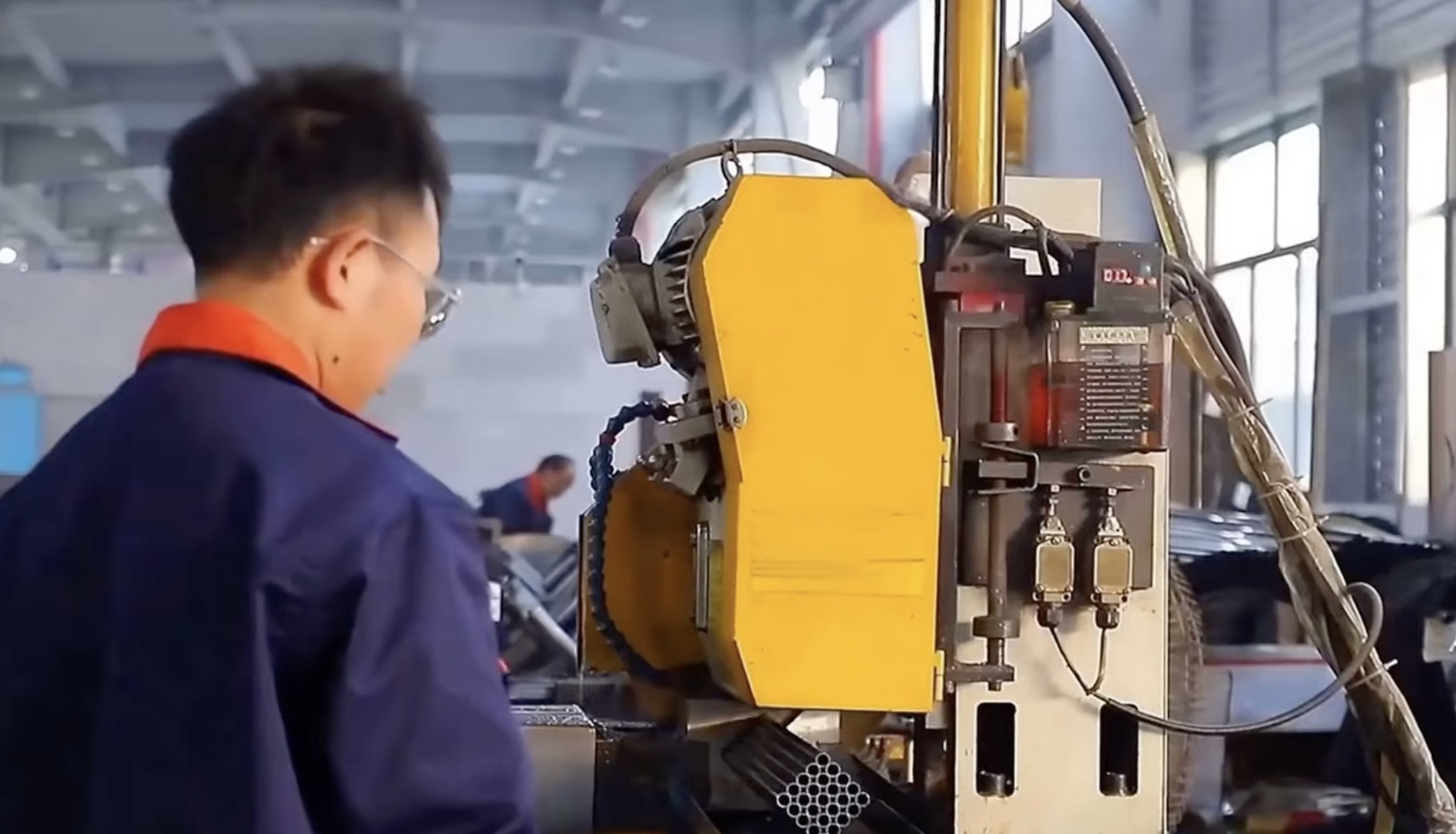

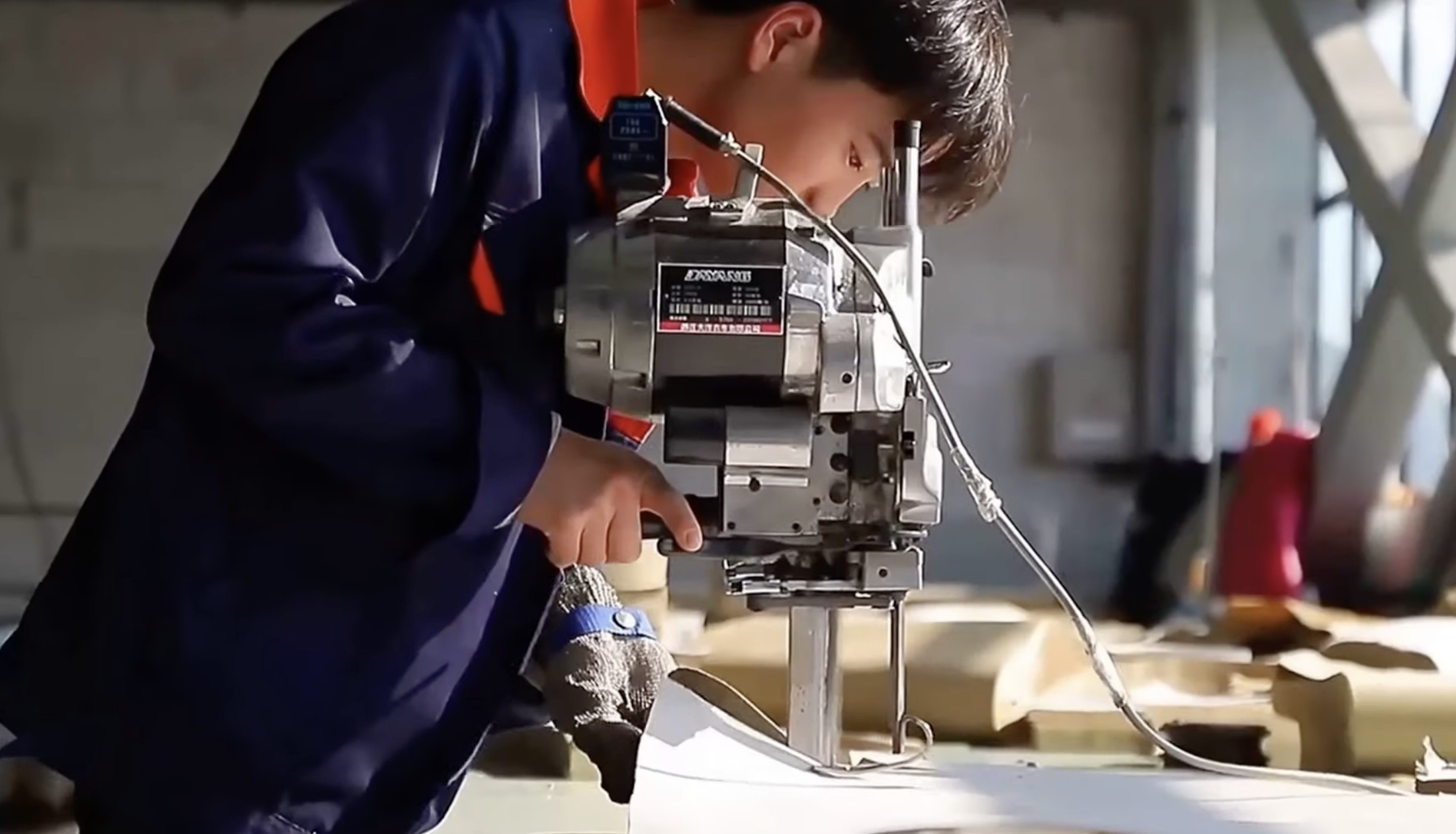

Fairwind operates a modern 30,000+ m² outdoor furniture factory designed for efficient, high-quality production. The facility integrates specialized zones for metalwork, fabric cutting, sewing, assembly, warehousing, and administration, along with a dedicated showroom and design studio.

Equipped with advanced metal surface treatment lines, template design systems, automated sewing machines, and flexible assembly lines, Fairwind meets diverse product design and manufacturing needs with speed and precision.

Quality is at the core of everything we do. We implement rigorous quality control measures at every stage, including raw material inspection, in-process checks and final product testing. Our factory follows international standards such as BSCI, ISO and EN581, ensuring all products meet durability, stability and safety requirements.

All raw materials and accessories, including fabrics, metal tubes, plastic parts and other accessories, are quality tested upon arrival. Through various methods such as random inspection and laboratory testing, we ensure that the performance and quality of each batch of raw materials meet production standards. Raw materials below the standards will not be accepted or used in product production

Semi-finished products are inspected at every stage of production before handing over to next process. All existing problems are solved promptly to ensure that problematic semi-finished products will not flow into the next process.

Before packaging of finished products, all produced items will be inspected to ensure that the goods can be used normally. Any products with quality issues will not be packaged or shipped.

We accept and welcome customers to send third-party inspectors to our company to inspect the goods before shipment. We can also send the products or materials to professional third-party testing institutions like SGS for testing according to customer requirements.

We are eager to hear your needs. Please fill out the form or email us at business-service@fairwindcamp.com, our team will get in touch with you in 12 hours.